Colex Introduces Latest Model

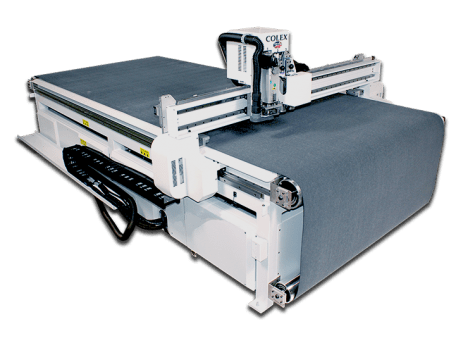

Sharpcut Flatbed Cutter Conveyor System

Colex, the industry leader in wide-format finishing solutions, features the Sharpcut Conveyor Flatbed Cutter System. The Sharpcut Conveyor is Colex’s most productive and value solution for automated finishing of wide format media. The new Sharpcut Conveyor can be used for a variety of applications. The conveyor system is designed to speed up the process of cutting soft to rigid boards, vinyl, fabric, and textiles by utilizing the automatic board feeder or the roll feeder allowing for faster production runs. The Sharpcut Conveyor is designed to operate with minimal operator intervention when equipped with the automatic board feeder or the roll feeder. This provides users with the best affordable digital cutting automation system.

Most shops have a router today, but traditional routers cannot efficiently perform the necessary specialized functions inherent in the versatile Sharpcut Conveyor tool library available. The Sharpcut Conveyor is special in that it allows finishing technicians to perform intricate cuts while operating fully automated. The Sharpcut Conveyor offers a Triple Interchangeable Tool Head station that selects the proper tool for the job and an energy efficient 6-Zone Vacuum System with a Vision Registration System. The Sharpcut Conveyor package includes a Fixed Knife, Oscillating Knife and a Router. The new and improved oscillating knife cuts at 14,000 strokes per minute cutting 50% faster along with a variety of new tools offered to customize the Sharpcut Conveyor to suit specific needs and workflow including the Universal Drawing Tool, V-cut Knife for 90 degree folds, Coroplast Knife, Creasing Wheel, Universal Single Edge Knife for Sintra up to 6mm, and the new motorized rotary knife for fabrics.

The Optiscout Vision Registration System features a high resolution color camera, the ability to import over 30 file formats, plug-in export data from CorelDRAW, Illustrator & AutoCAD desktop to the Optiscout desktop, user friendly material library and the ability to read any diameter registration mark, crop mark or square resulting in highly efficient production.