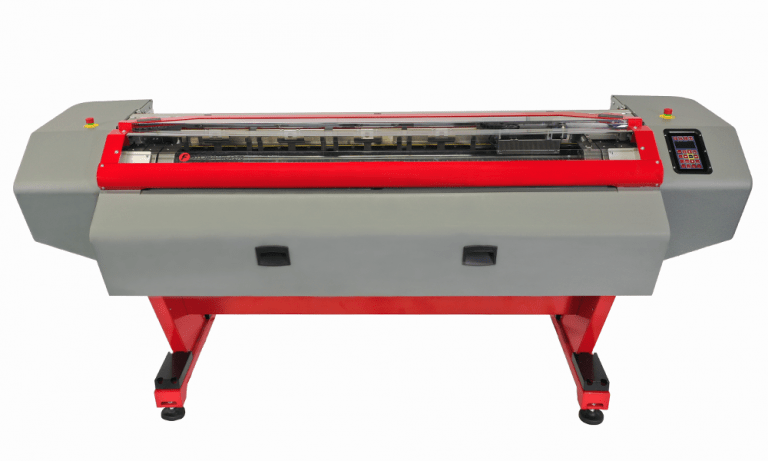

Fotoba XLA 170

Fotoba XLA 170 Digital Cutter

Fast | Productive | Precise | Reliable

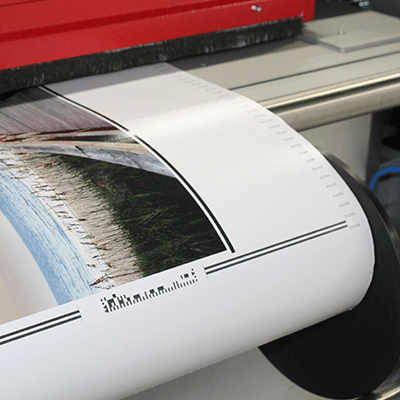

FOTOBA CUTMARKS are embedded in most popular RIP softwares.

The XL Series can handle media with a maximum thickness of 40 mil including polycarbonate, laminates and encapsulated media, photo paper, vinyl, self-adhesive vinyl, graphic arts film, duratrans, canvas and much more.

Bar Code Reader

Intuitive Touch Screen

Industrial Build

Supported RIPs