Sharpcut Flatbed Cutter Details

HN Media Andy2023-06-12T13:22:21-04:00Sharpcut Flatbed Cutter Details

Productivity

The Colex Sharpcut is an affordable solution for those looking to grow their business. This complete turnkey solution will help automate the print service provider’s workflow and reduce costs associated with the finishing process of large format goods. This will open the doors to new opportunities, reduce costs, and help increase production while tapping into new revenue streams.

Cut Quality and Precision

The Colex Sharpcut is manufactured with a solid steel-welded frame, which helps to minimize any vibration in the flatbed while you are routing/cutting. This allows the Sharpcut to produce a near flame polish on your materials, with the capability of routing up to 2.5 inches thick!

Vacuum Quality and Material Hold Down

The work surface is divided into six zones for the 67″ x 126″ and 126″ x 64″ models, four zones for the 67″ x 67″ model, and sixteen zones for the 126″ x 126″ model. Each zone has its own vacuum pump controlled by individual electrical “on/off” buttons on the front panel. The power of the pumps is configured for most substrates used in large format printing.

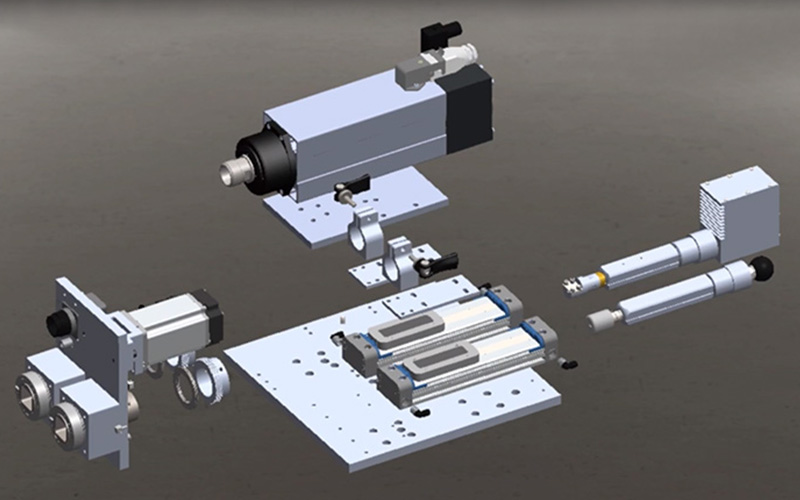

Interchangeable Tool Head

The unique design of the Colex Sharpcut’s triple interchangeable tool head allows your operator to transition from routing, knife-cutting, and kiss-cutting rapidly. By default, the Colex Sharpcut includes a fixed knife, an oscillating knife, and a router, allowing you to maximize the full capability of the table for a multitude of applications. Optional add-on tools are available for customization to suit your specific needs and workflow.

Design Concept

The Colex Sharpcut production power and quick tool change ensure on-time delivery, even for the most complex jobs. Whether the job requires cutting sheets or rigid materials, the Colex Sharpcut always delivers clean, smooth, and accurate edge quality. The gantry’s X/Y axis movement is driven by a rack and pinion system that increases the longevity and endurance of the cutter when comparing it to a belt-driven system. The rack and pinion system is powered by Panasonic Servo Motors and requires minimum maintenance, driving down the cost of owning the Colex Sharpcut.